We order bare boards from trusted fabricators, managing specifications, layer stackups, lead times, and quality requirements to ensure boards arrive ready for assembly.

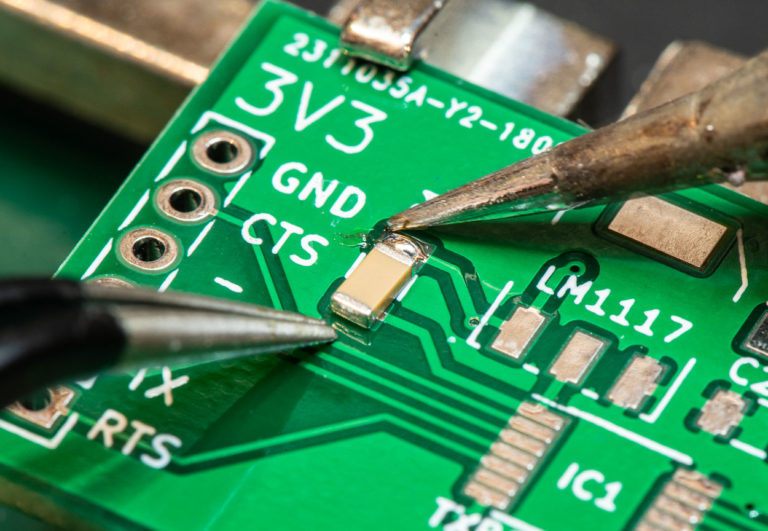

We solder both surface mount and through-hole components in-house. From simple single-sided boards to dense, multi-component assemblies, we build each board carefully and inspect it before moving to programming.

Firmware developed by our engineering team during the design phase is loaded and configured on each board immediately after assembly. Because the same team wrote the code, programming and initial bring-up happen without delay.

Each assembled board is tested against its design requirements - verifying power, signals, communication, and control functions. When issues are found, we diagnose and resolve them in-house, often the same day. Design updates are fed directly back to the engineering team for the next board revision.