Complex products need structure. We break your product down into connected components, subsystems, and modules - defining interfaces, managing dependencies, and organizing the design so it can be developed, manufactured, and serviced efficiently.

When you're improving an existing product or developing the next generation, we start by scanning or measuring what you already have. This gives us an accurate digital model to work from, ensuring the new design builds on a solid foundation.

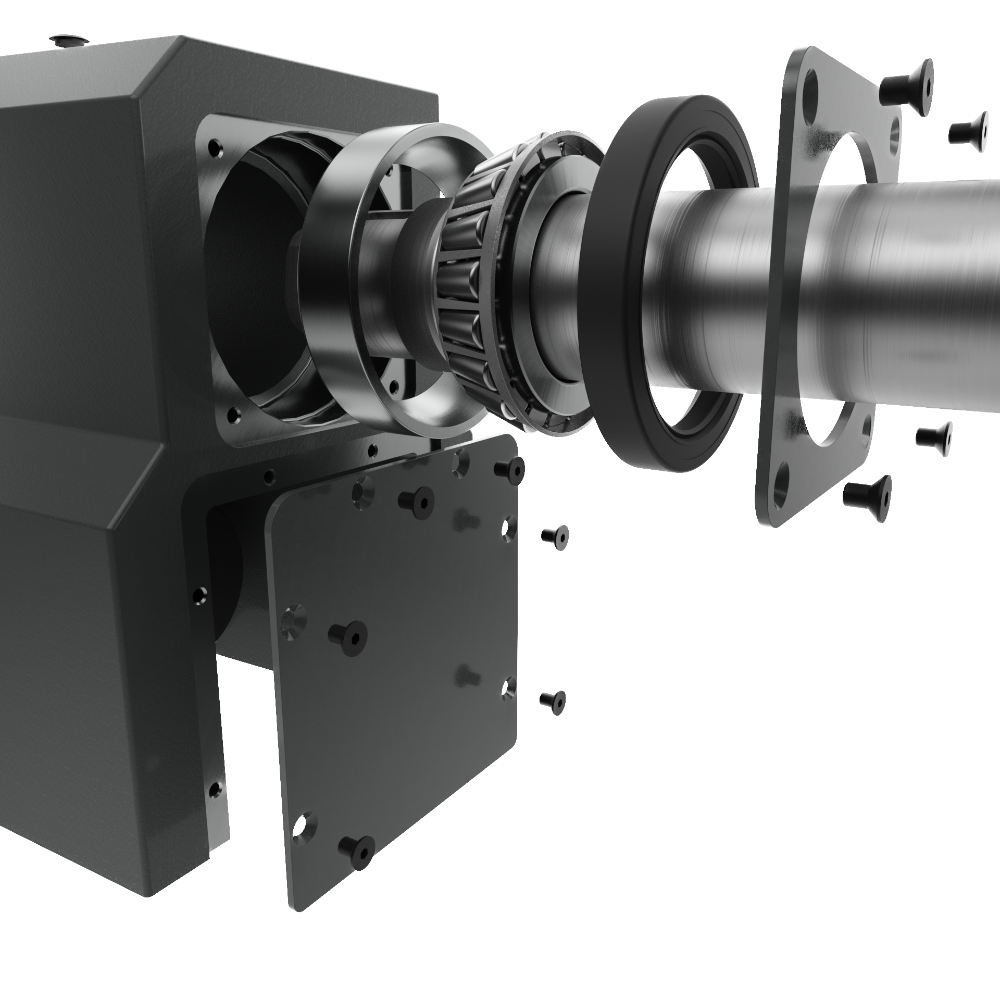

We create detailed solid and surface models of every component and assembly in your product. Parametric design allows for fast iteration as the design evolves, and the complete digital definition serves as the single source of truth for analysis, prototyping, and manufacturing.

The look and feel of your product matters. We address form, ergonomics, and aesthetics alongside the engineering - ensuring the product is not only functional but also appealing and intuitive to use.

We optimize every part for its intended production method - machining, fabrication, sheet metal, injection molding, casting, 3D printing, and more. DFM ensures parts can be made efficiently and cost-effectively.

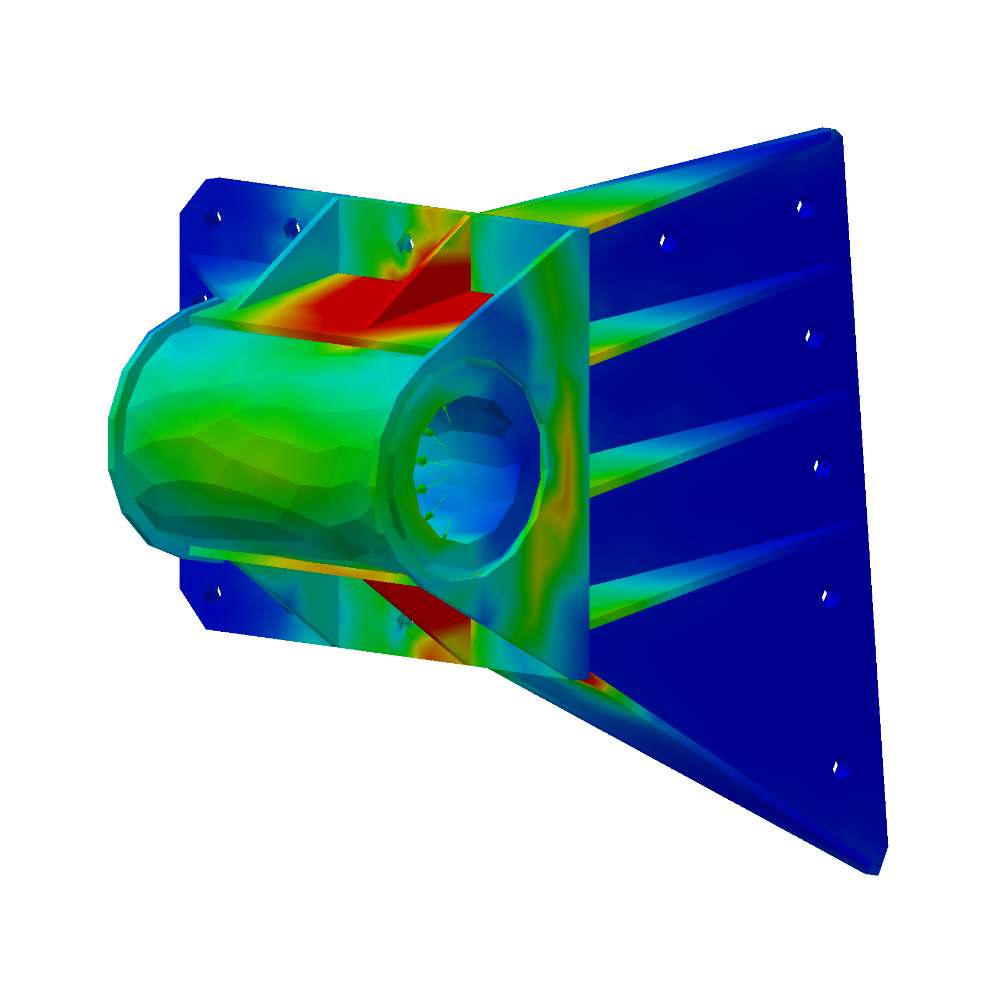

Using Autodesk Nastran, we perform advanced simulations to validate your product's performance before prototyping. Our capabilities include linear and nonlinear static analysis, buckling, modal analysis, transient and frequency response, shock and drop tests, fatigue, and heat transfer.

For products involving fluid flow or thermal management, we analyze airflow, liquid flow, and heat transfer. Applications include electronics cooling, hydraulic and pneumatic systems, free water surface effects, and other complex scenarios.

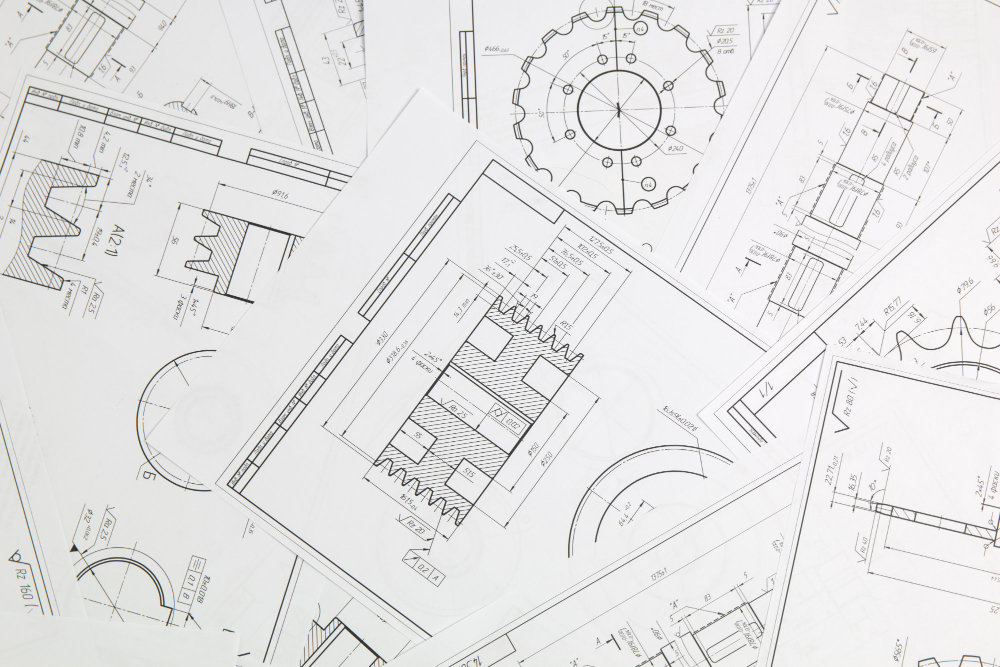

We produce professional, fully dimensioned and toleranced drawing packages ready for manufacturing. This includes geometric dimensioning and tolerancing (GD&T), bills of materials, revision control, and all the documentation your manufacturer needs.

At key milestones throughout the project, we conduct structured design reviews to ensure alignment between our engineering team, your team, and manufacturing requirements. These reviews catch issues early - before they become expensive to fix.