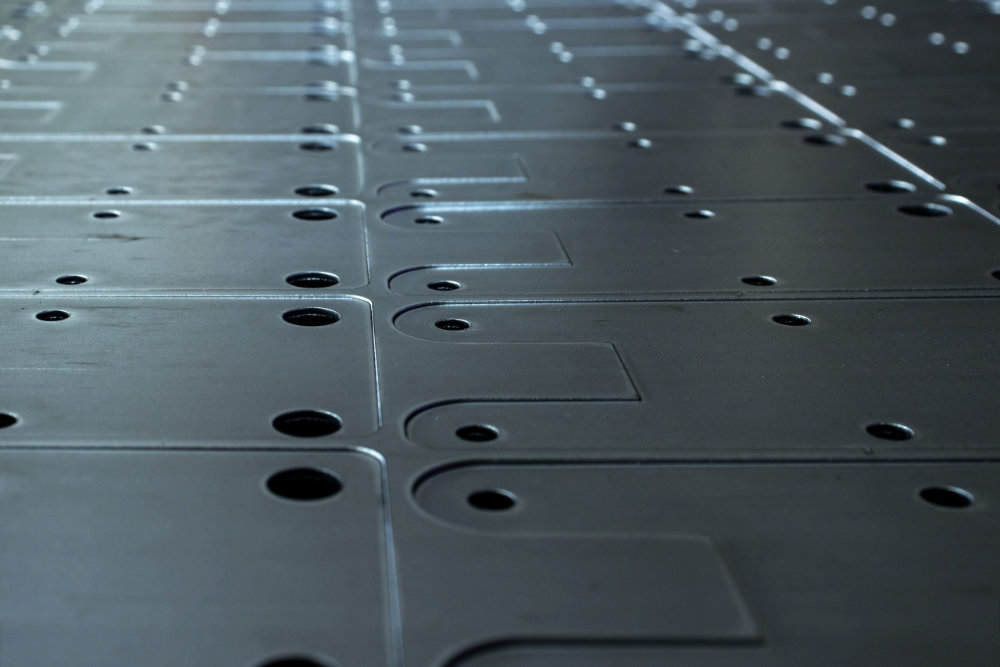

Our dual-source laser features a 1,200W fiber laser for metals and a 130W CO2 laser for non-metals. The working area is 1,380 x 920 mm (54.3 x 36.2 in) with pass-through capability for longer materials. The fiber laser cuts up to 10 mm carbon steel, and handles thinner gauges of stainless steel, aluminum, brass, and copper with precision and clean edges.

Both laser sources support engraving and marking. The fiber laser engraves metals - adding logos, part numbers, serial numbers, and graphics directly to steel, aluminum, and other metal parts. The CO2 laser engraves plastics, wood, leather, and other non-metals.

Our press brake forms precise bends in sheet metal - producing brackets, enclosures, channels, flanges, and other bent components. Bend sequences are planned alongside the flat pattern design to ensure accurate, repeatable results.

TIG and MIG welding cover all common metals and joint types. For thin materials where heat distortion and cosmetic appearance are critical, the M3 Ultra doubles as a laser welder - producing clean, precise joins ideal for visible welds on product enclosures and cosmetic parts.

We work with carbon steel, stainless steel, aluminum, brass, copper, and other sheet metals. The CO2 laser extends our capabilities to non-metals including wood, acrylic, rubber, leather, and other materials - useful for gaskets, panels, signage, and mixed-material prototype components.