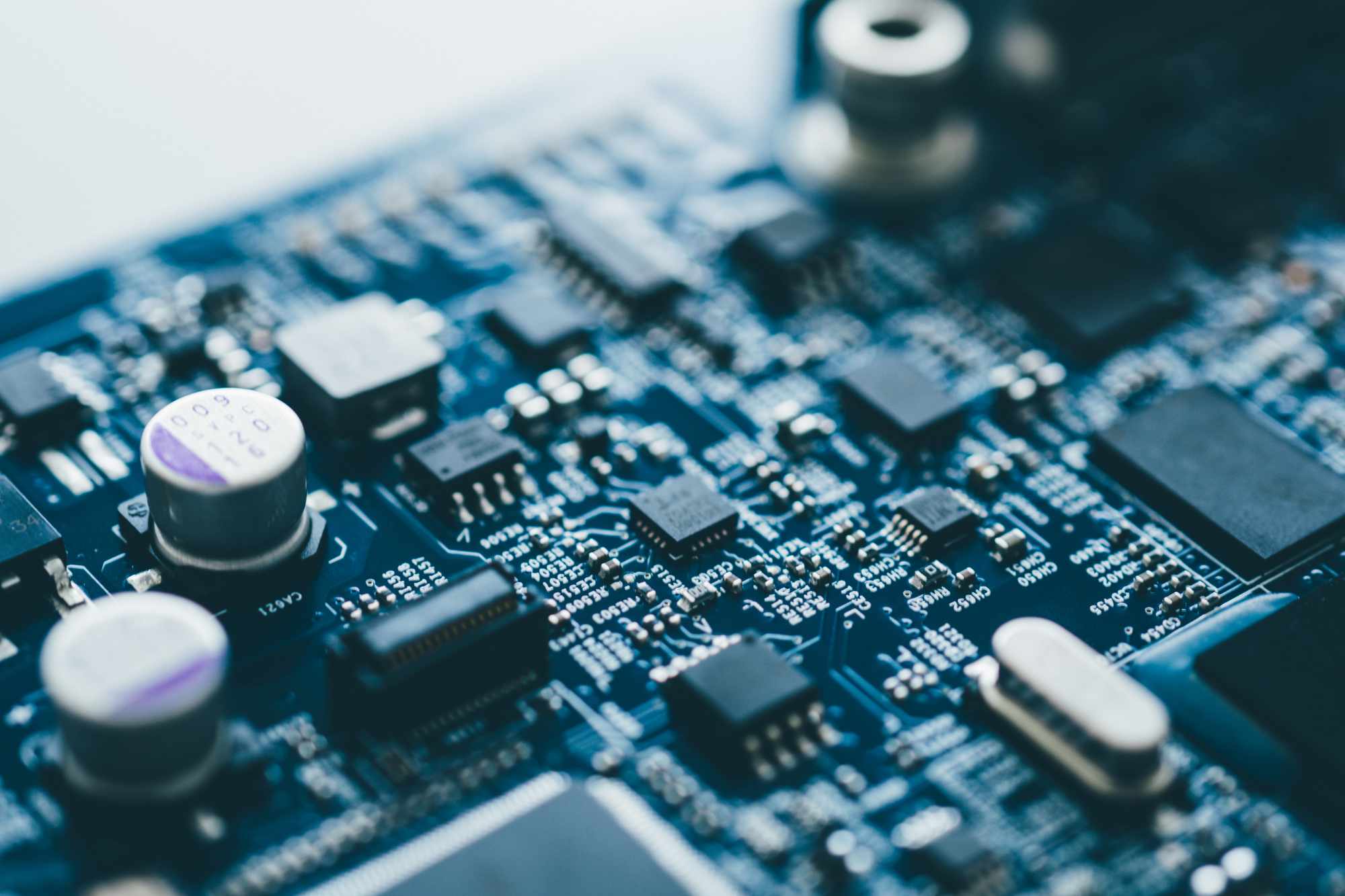

We design the complete electrical system for your product - power distribution, signal conditioning, sensors, actuators, communication interfaces, and control logic. This includes selecting components, defining the circuit architecture, and creating detailed schematics.

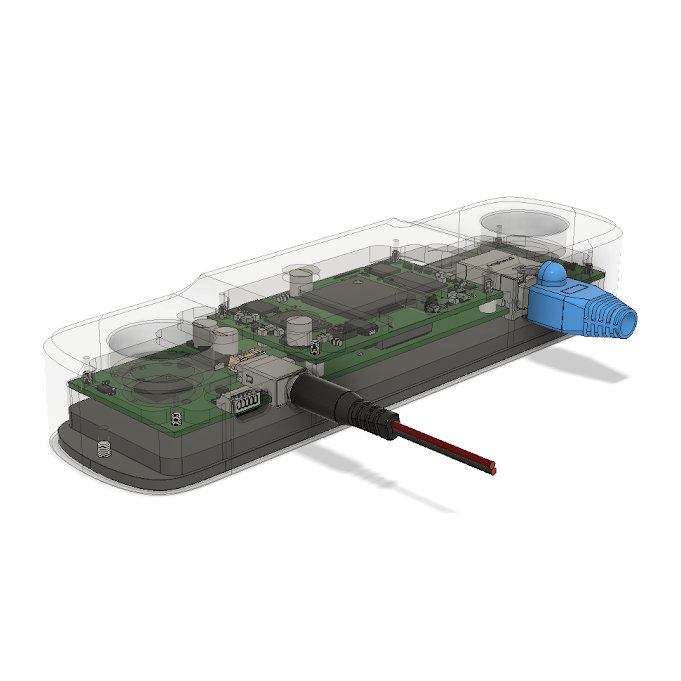

We translate schematics into physical board designs, handling component placement, trace routing, signal integrity, thermal management, and design for manufacturing. The layout is optimized for the product's mechanical constraints and the intended production process.

We write the embedded software that controls the hardware - from simple sensor interfaces and motor controllers to complex control systems with multiple communication protocols. Firmware is developed and tested alongside the hardware design.

We assemble boards in-house with both SMD and through-hole soldering, then program and functionally test each unit. Because the same team that designed the circuit and wrote the firmware is doing the assembly, we can debug issues immediately and iterate without delay.